Chain Scraper Cleaning Sin is used for cleaning broken waste plastics. Used for cleaning and separating household electrical materials, small and large noises, containing silicone, wood, and sponge plastic.

Using clear water/saltwater to produce different floating effects on different materials, cleaning and separating various plastics such as PP, PE, ABS, PC, PA, PVC, metal, silicone, wood, sponge, etc

Multiple sinks can be used together to separate and clean multiple materials at once.

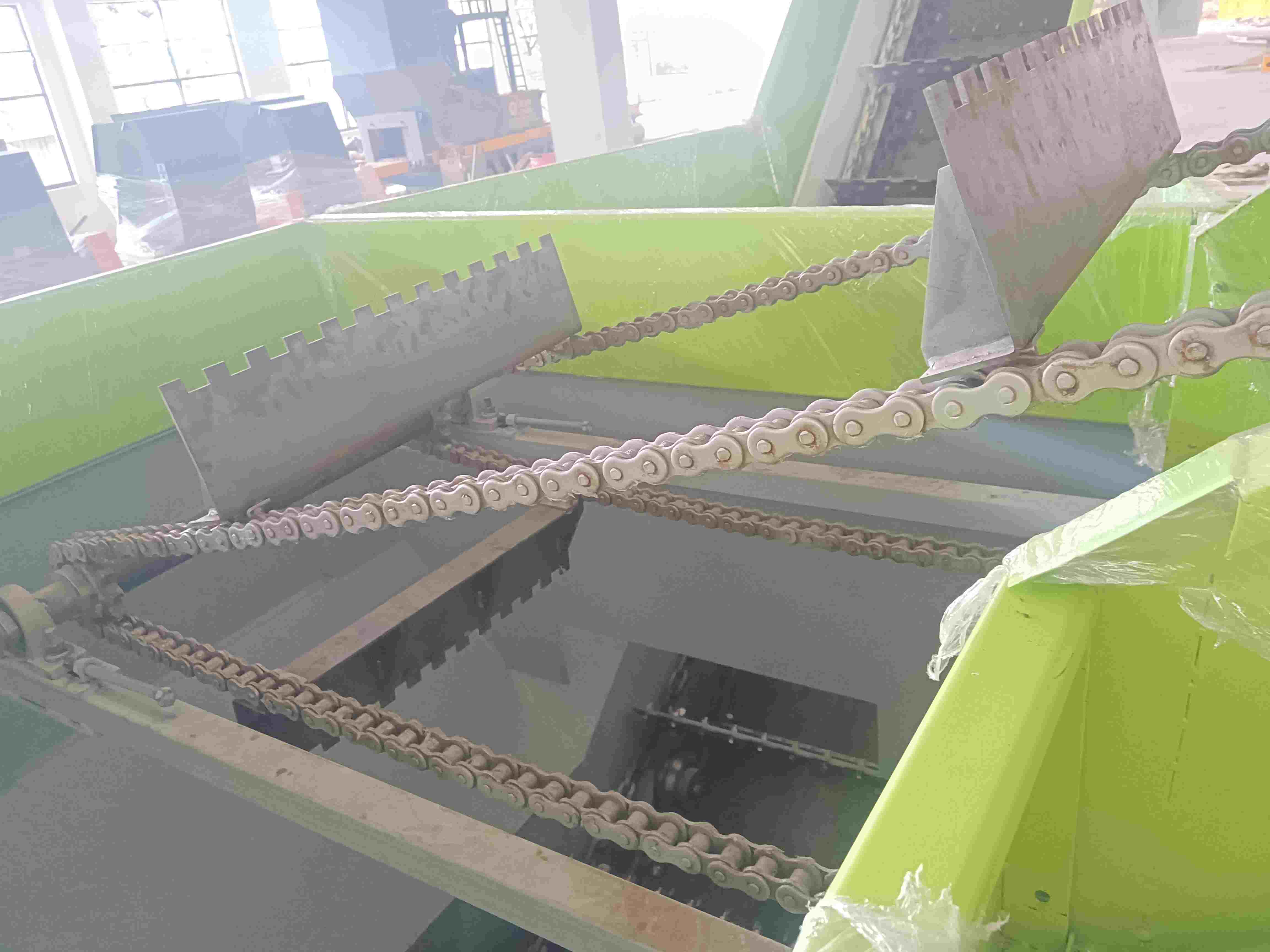

Easy to maintain, links, scrapers, feeders, etc. can all be replaced independently.

Chain Scraper Cleaning Sin has excellent cleaning and separation effects and high output, which can meet the cleaning and separation needs of professional solid waste treatment factories.

Can be used in conjunction with an electrostatic silicone sorting machine.

Solved the problem of leakage in the old sink

characteristic:

1. The bottom material is discharged using a chain drag method, which solves the problem of incomplete transportation of bottom material in old water tanks. The separation of materials and mud, sand, and metal is relatively clean, reducing material loss.

2. Solve the problem of water leakage at the connection of the old sink, this sink sheet metal is formed and sealed in one go

3. The chain drag method for discharging materials has a higher motor power and output compared to the previous bottom twisting cage method.

4. High quality manganese steel chains and stainless steel scrapers are used for the discharge part of the sediment. Low failure rate and long service life.

5. The floating material discharge part adopts a feeder and a combination of stainless steel chain and stainless steel scraper, which has high discharge efficiency and strong adaptability.

6. There are few restrictions on materials, and it is also applicable to household appliances such as metal, mud, sand, sponge, wood, silicone, and materials with large and small noise.

7. The sinking material discharge end, floating material discharge end, upper baffle, feeder, and ladder can all be disassembled for easy discharge and packing. Reduce transportation restrictions and save transportation costs.

8. The sinking material discharge end, floating material discharge end, upper baffle, feeder, and ladder can all be disassembled and repaired separately, making maintenance convenient for ordinary operators.

9. The overall sheet metal processing of the sink, with all components being CNC cut and completed in one go. The surface smoothness is high, the sealing at the connection is complete, and the production process is much more complex than before.