Youxin is a 500 Model Double Shaft Shredder manufacturer. We independently develop and manufacture, and can provide services from core components to complete machine assembly to ensure reliable equipment quality.

Our 500 Model Double Shaft Shredder is suitable for laboratories, small processing points, schools or start-up projects. It can effectively crush common small waste materials, with low site power requirements and flexible deployment. It can tear the materials into relatively small pieces. The most important thing is low operating cost, almost maintenance-free, worry-free and durable.

Waste small household appliances: blood glucose meter, blood oximeter, hand dryer, heating pad, massager, electric toothbrush shell, etc.

Lightweight packaging waste: waste cardboard, waste paper, corrugated paper, plastic bottles, thin-walled plastic containers, etc.

Other common laboratory waste: small plastic or metal parts, circuit board scraps, etc. Mainly suitable for coarse crushing and pre-crushing links

The 500 Model Double Shaft Shredder is a relatively small machine with low power. It does not require high electrical capacity in the factory environment.

Small size: small footprint, very convenient for mobile or fixed installation, and easy to enter places with limited space such as school laboratories, small workshops, and R&D centers.

Noise control is relatively good: compared with large equipment, the operating noise is more acceptable and suitable for places with certain requirements for the working environment.

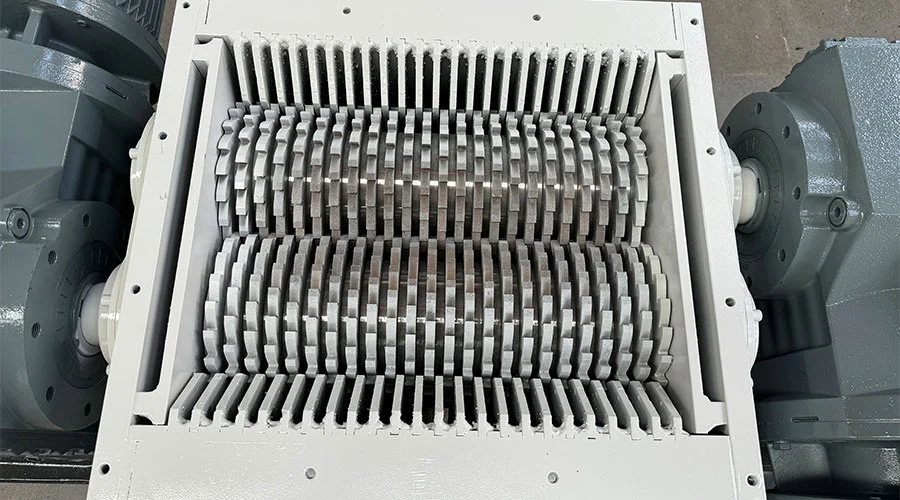

The 500 Model Double Shaft Shredder has a large number of teeth, which can tear the material smaller. This machine is very useful for laboratories and small workshops that generally do not need to recycle and just crush the material. There is no need to consider the problem of changing and sharpening the knife, and the pressure on later maintenance and after-sales is very light.

High-quality manufacturing: relying on the strict quality control of its own factory, key components (such as knife shafts, bearings, and boxes) are made of high-quality materials and processes to ensure that the equipment is sturdy and durable.

Revolutionary low-maintenance design:

Extremely long tool life: Designed for handling light materials, the tool wears slowly, greatly extending the tool change and sharpening cycle.

Significantly reduce maintenance pressure: There is almost no need to consider tool maintenance issues frequently, which greatly saves later labor costs, spare parts costs and downtime.

Worry-free after-sales: As the source manufacturer, we provide timely and professional after-sales service and technical support, so that you can buy and use 500 Model Double Shaft Shredder with more peace of mind. The equipment structure design also strives to be simple, which is convenient for daily inspection and simple maintenance.